3 chemicals you need in your workshop (and what to use them for)

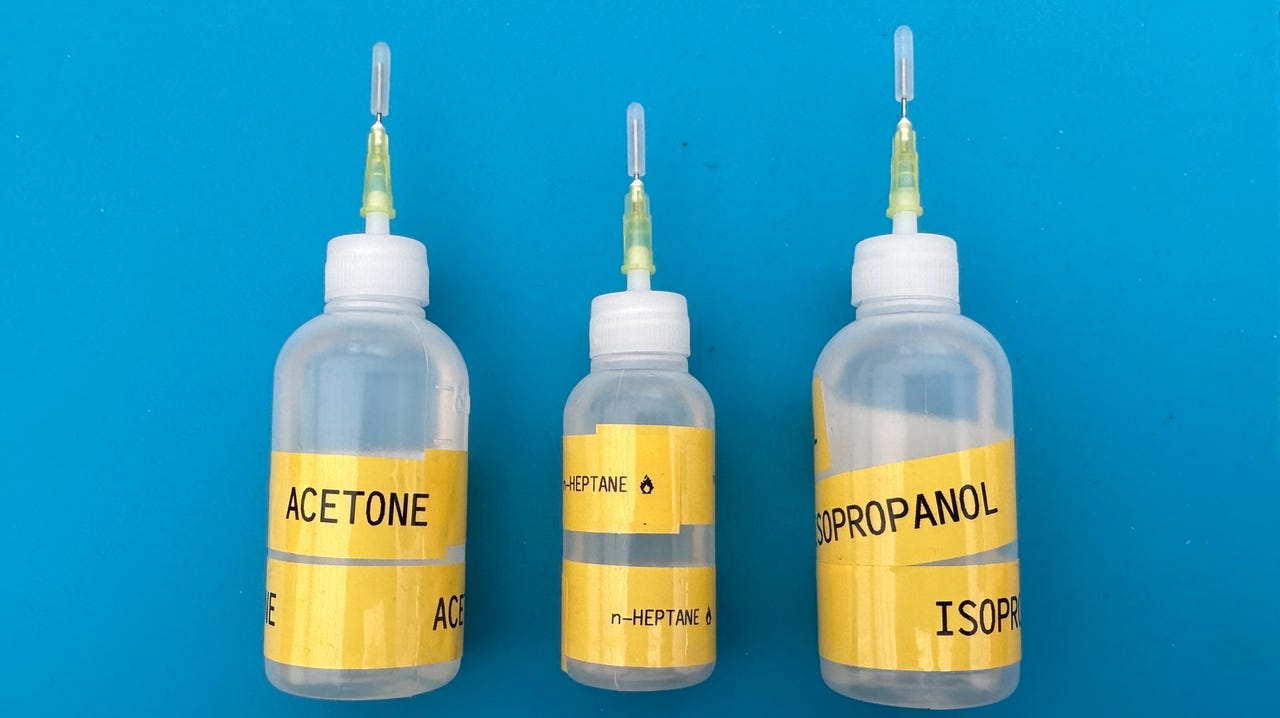

The three chemicals in question: Isopropyl alcohol (IPA), acetone, and n-heptane Adrian Kingsley-Hughes/ZDNET

A proper, functioning workshop needs more than tools. Sometimes, having access to the right chemicals can make all the difference.

Also: Need cutting blades for your workshop? Forget metal and go ceramic

The three chemicals I'll discuss below have numerous uses, from cleaning circuit boards, wiping the print bed of your 3D printer, and removing sticky labels.

Safety first

Before I introduce the chemicals, here are a few safety precautions I strongly recommend you follow:

- Keep away from naked flames

- Wear protective gloves

- Avoid spills (and mop up any spillages promptly)

- Work in a well-ventilated area

- Keep chemicals away from children

1. Isopropyl alcohol

Isopropyl alcohol (IPA) is a chemical that I use frequently, thanks to its wide-ranging applications.

- Cleaning electronics: IPA's quick-drying and non-conductive nature makes it ideal for cleaning electronic components, circuit boards, and connectors without causing damage.

- Removing hot glue: A couple of drops of IPA will lift cooled hot glue off most surfaces.

- Removing residue: Isopropyl alcohol can remove adhesive residue, stickers, or tape marks from various surfaces, leaving them clean and free of gunk.

- Disinfecting tools and surfaces: With its antimicrobial properties, IPA is perfect for disinfecting tools, work surfaces, and equipment, keeping your workshop clean and safe.

- Prepping surfaces: IPA can be used to clean surfaces before painting or gluing, ensuring a better adhesion and finish.

- Glass cleaner: Mix isopropyl alcohol with water to create a streak-free glass cleaner for windows, mirrors, and other glass surfaces in your workshop.

- Degreaser: Isopropyl alcohol can cut through grease and grime on machinery, tools, and parts.

2. Acetone

Acetone is an indispensable asset to any workshop, due to its versatility and effectiveness.

- Cleaning agent: Acetone's powerful solvent properties make it perfect for cleaning tools, removing grease, and getting rid of paint residue or glue.

- Removing adhesives: Acetone can break down stubborn adhesives like super glue or epoxy, making it easy to remove them from surfaces or tools.

- Dissolving plastics: Acetone can dissolve certain plastics, such as ABS, making it useful for bonding, smoothing, or reshaping 3D printed objects or plastic components.

- Removing ink and stains: Acetone can help eliminate ink, marker, and other stains from a variety of surfaces, including metal, glass, and plastic.

3. n-heptane

n-Heptane, a highly effective and fast-evaporating solvent, can be an essential tool in the workshop.

- Adhesive remover: n-heptane can be used to break down and remove adhesives, stickers, or tape residues from various surfaces without causing damage.

- Degreaser: As a powerful solvent, n-heptane works effectively as a degreaser for machinery, tools, and parts in your workshop.

- Paint thinner: It can be used as a paint thinner for certain types of paints and coatings, ensuring a smoother application and finish.

- Ink and stain removal: Different stains can respond to different solvents, and n-heptane can help eliminate stubborn ink, marker, and other stains from a variety of surfaces, including metal, plastic, and glass.

The brushes I prefer

I use an old toothbrush, or one bought special for the task at hand. Another good alternative is to use what are called “acid flux brushes,” which are a lot cheaper than toothbrushes.

Why I use these dispensing bottles

While I keep the bulk of my chemicals in their original bottles, nothing is going to ruin your day faster than spilling a quart of any of these chemicals on your bench, floor, or carpet. Not only do they smell, and carry a risk of fire, but they can damage surfaces.

Also: This stuff is better than super glue

This is why I decant a small amount — no more than 15 ml/0.5 fl oz — into spill-free dispensing bottles that have applicator needles fitted.

These are great for dispensing small amounts of the chemicals into exactly where you need them.

These spill-free dispensing bottles are awesome! Adrian Kingsley-Hughes/ZDNET

How to make bottle labels

I use my Brother PTE-300 industrial label maker to make labels for my dispensing bottles. These labels resist chemical attacks and last far better than printed or hand-written labels.

Also: Why I love my heavy-duty label maker so much